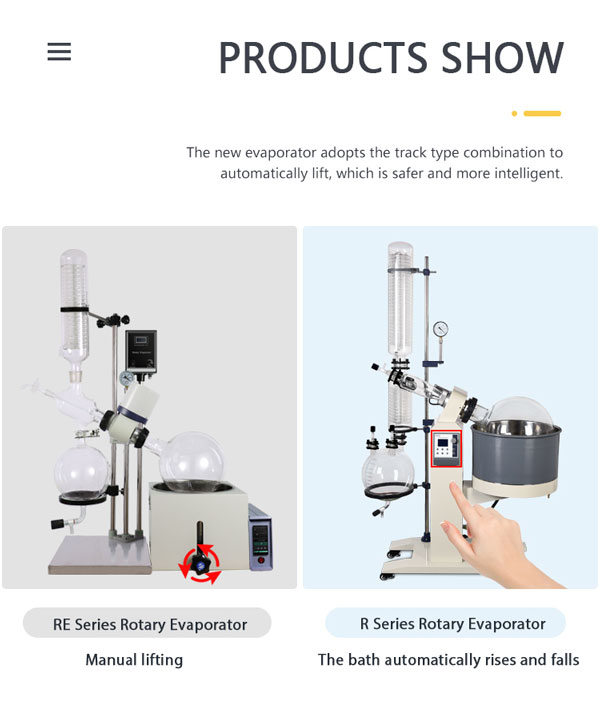

Industrial Rotovap Distillation Thc Manufacturer

ZZKD rotary evaporator:

A rotovap machine known as a rotary evaporator, is an instrument used within the laboratory to continuously distill a large amount of risky solvents underneath lowered pressure conditions, which may separate and purify the reaction products. The rotary evaporator is especially composed of a rotary motor, an evaporating tube, a vacuum system, a fluid heating pot, a condensing tube, and a condensing pattern assortment bottle. The working principle is that the evaporation flask is in a unfavorable strain state by way of a vacuum pump, and the flask is rotated at a continuing pace at an acceptable speed through electronic management to increase the evaporation space. Soke purchasing steward realized that the rotary evaporator system could be sealed and decompressed to 400-600 mmHg, and the rotation speed can attain 4-200 rpm, so that the solvent can kind a skinny movie and increase the evaporation space. The drive generated by the rotation can effectively inhibit the boiling of the answer.

Innovation of ZZKD rotary evaporator:

The rotary evaporator r1050 steam structure is simplified, and the fully modular aluminum alloy physique is more compact as a complete. Constant drive lifting and deal with locking system, simple to operate. Vertical three-circuit large-area high-efficiency condenser. The PTFE patented sealing rotovap distillation thc can keep a excessive vacuum degree above -0.098Mpa and might stand up to various solvents. Other merchandise available on the market are not so small and delicate, and the lifting methods are also different.To buy a high-efficiency rotavapor industrial, you have to consider the next components:

How to choose on rotavapor industrial?

1. Select the scale of the rotary evaporator based on the experimental needsWhat is the amount of distillation required for one experiment? How many distillation samples are there? What solvents are distilled? What are their boiling points? Through the above questions, determine what temperature vary of rotovap distillation thc is required, what stage of temperature management accuracy must be, and the way massive the quantity of the evaporation flask and assortment flask ought to be. Generally speaking, the capability of the laboratory-grade rotavapor industrial is lower than 5L, and the industrial-grade CNC rotary evaporator can be adapted to the large-capacity rotovap distillation thc bottle of 20L.

2. Vacuum is the most important indicator

Under the corrosion of varied solvents and within the state of motion, whether or not the system can preserve a high degree of vacuum is the most important criterion for measuring the rotavapor industrial. Choose a rotavapor industrial with Teflon material and glass sealing, which is resistant to various solvents, has lasting and reliable air tightness, and can maintain a excessive vacuum degree above -0.098MPa.

3. Selection of heating pot and heating medium

The heating pan temperature should be 20 degrees above the boiling level of solvent evaporation. Note that the boiling point of the solvent underneath vacuum could additionally be completely different from that beneath regular circumstances. The heating medium usually adopts tap water or distilled water. If the heating medium is silicone oil, the ignition point is a minimal of 25°C larger than the utmost temperature of the heating pot.

4. Selection of condenser

There are two widespread forms of condensers in the marketplace, vertical condensers and inclined condensers. The vertical condenser occupies a small area, and the large-capacity rotavapor industrial chooses the vertical condenser to avoid wasting space.

5. Optional explosion-proof glass assembly

Distilling flammable and explosive solvents, it is recommended to determine on glass elements with explosion-proof coating. Choose a rotary evaporator with computerized deflation perform to avoid explosion as a result of poor management of guide deflation.

6. Parameters Affecting Evaporation Efficiency

Understanding the factors that have an result on the distillation effectivity of rotary evaporators will allow you to to better select suitable merchandise and acquire the most effective experimental outcomes via appropriate experimental operations. Soke Purchasing Manager has summarized the following elements that affect the efficiency of the rotary evaporator for your reference.

Features of rotovap distillation:

(1) The vacuum worth of the system, probably the most critical issue is the fabric of the vacuum pump, sealing ring and vacuum tube.(2) The temperature of the heating pot. The higher the temperature, the quicker the distillation impact, however considering the heat sensitivity of the ingredients and the safety of the operation, a generally used temperature is 60 degrees Celsius. It is mostly really helpful to lower the vacuum value to realize quicker distillation efficiency.

(3) The rotation speed of the rotovap distillation thc bottle. The faster the rotation velocity, the bigger the heating area, but at the similar time the thickness of the liquid film is also thicker, which will increase the heat transfer temperature difference. Therefore, supplies with totally different viscosities have different optimum rotation speeds.

(4)The temperature of the cooling medium. It is mostly recommended to keep up a temperature difference of 40°C between the cooling medium and the heating pot, which may improve the condensation effectivity and scale back the impact of steam on the vacuum of the system.

Rotary evaporator for sale:

Rotary evaporators are mainly used for focus, crystallization, drying, separation and solvent recovery in the pharmaceutical, chemical and biopharmaceutical industries. The precept is: under vacuum circumstances, constant temperature heating makes the rotary bottle rotate at a relentless speed, and the fabric forms a large-area movie on the bottle wall, which evaporates efficiently. The solvent vapor is cooled by a high-efficiency glass condenser and recovered in the assortment bottle, which significantly improves the evaporation effectivity. It is very appropriate for the concentration and purification of biological merchandise which are simply decomposed and denatured at high temperature.

The firm's rotary evaporator integrates the essence of comparable products at home and abroad, and accumulates the company's profitable practical experience. It has formed 2L, 3L, 5L, 10L, 20L, 50L sequence. The product design follows the ideas of excessive effectivity, practicality and economic system. Everything is for the sake of users.