50l Rotary Evaporator For Sale

50L Rotary Evaporator:

Rotovap machine is suitable for chemical labs to remove solvents from samples efficiently and easily by evaporation. The rotational evaporation course of is frequently used to separate waters with low boiling focus, corresponding to n-hexane or ethyl acetate, from energetic mixtures at room temperature and stress.

However, the exact utility also allows the removal of a soluble substance from a sample containing a fluid compound if there are little evaporation and sufficient boiling contrast centered on the selected temperature and stress discount.

The Structure of 50L Rotary Evaporator-50 Liter Rotovap

he 50L rotary evaporator is a device utilized in chemical laboratories to take away solvents from samples efficiently and smoothly by evaporation. Thus, the rotary evaporation course of is commonly used to separate low boiling solvents, corresponding to n-hexane or ethyl acetate, from lively mixtures at room temperature and strain.

Current 50L rotary evaporators can be designed for manufacturing and production using geared up high capability flasks.

The 50L rotary evaporator adopts the evaporation zone by expanding the flask at low pressure, to make the solution in the diffuse jar evaporate. They are the important and ideal equipment for the chemical business, the pharmaceutical business, the basics of higher education, and the logical analysis laboratories.

Besides, rotovap has an engine particularly with gears and worms, which offers constant rotation at speeds ranging from 10 to one hundred eighty pm. When a vial containing a soluble substance is rotated, it constantly transports a small layer of liquid over the entire inside floor. This provides an enormous floor area for evaporation brought on by the light heating of the water tub.

Moreover, the circulation system is supplied with a particular seal, permitting the gadget to be positioned under vacuum, which adequately reduces the boiling of solvents and eliminates the vapor section, making the process more environment friendly. Further, each unit an easy-to-use vacuum release and a steady feed system, which lets you drag the melt constantly right into a rotating flask without ready for the method to cease.

Rotary evaporator application:

50L rotary evaporator application is suitable to analyze the evaporation, distillation, or separation of chemical substances. It usually works with a vacuum siphon that rotates with water and recycles the chiller in a comprehensive system to satisfy manufacturing and experimentation conditions.

Features of 50L Rotary Evaporator:

● The 50L rotary evaporator kit is convenient with a 50-liter evaporation flask and a 20-liter assortment flask.

● Rotary vacuum evaporator underneath vacuum circumstances, give fixed warmth to the bubble flask, it's going to rotate at a constant velocity, and the liquid can form a big space movie on the wall of the jar.

● 50L rotary evaporator parts: soluble steam is cooled by a high-efficiency glass condenser and recovered within the accumulator bottle, which significantly improves evaporation productivity.

● The 50L rotary evaporator is especially suitable for the focus and purification of organic components that may easily collapse and deform at excessive temperatures.

● Polyethylene and flexible evaporators are used in the sealing process and assure a high vacuum and an adjustable rotation pace.

The Advantages of 50L Rotary Evaporator:

● Advantages of using a rotary evaporator: Patented Teflon double seal innovation and PV flexibility ensure the extent of negative strain.

● The computerized switching valve makes steady accumulation impossible without affecting the vacuum and without stopping distillation.

● Teflon discharge valve is consumable and doesn't contaminate.

● The water jacket protects the operator from sizzling liquid burns.

● Lift a water bath with a motor for precise control.

● The PID temperature control guarantees precise temperature control.

● The elective stainless-steel flask holder with silicone pads is designed for safer loading and unloading of the flask.

Precautions During Loading of The 50L Rotovap:

● The 50L rotary evaporator should be returned in a shock-resistant padded case, marked with an “inclined” outdoors the case and punctiliously handled optical or electrical instruments, accurately placed, strictly prohibited from intense pressures, and accompanied if essential in the tools.

● The 50L rotary evaporator within the engine transmission should keep away from volatility and vibration, and should usually be positioned in entrance of the soft palate, or by individuals hanging from the legs or backpack mounted on the base of the cabinet.

● The steam should be maintained vertically so that the device can keep the state of the siphon vertically and should not be transported horizontally on the shoulder to keep away from damaging the system or the column system. Turn the system.

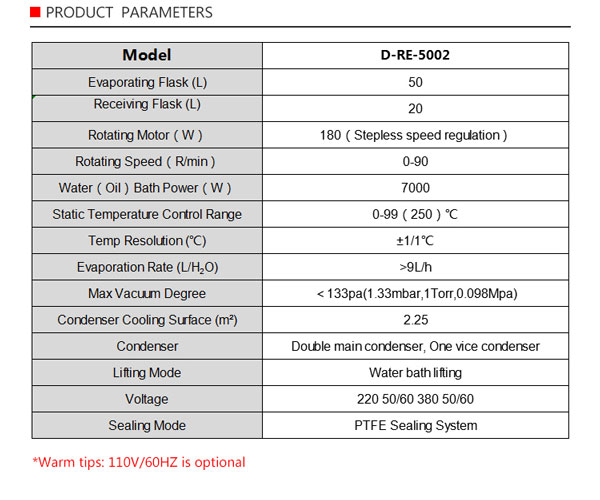

The Specifications of 50l Rotary Evaporator:

Precautions When Unloading, Filling, and Closing The 50L Rotary Evaporator:

●After turning on the 50L rotary evaporator find out the comparison positions for all components. When removing the gadget, hold the stand with one hand and the base with the opposite facet or progressively remove it with both sides. The use of a horizontal axis by hand is strictly prohibited.

●Fix the tripod before eradicating the system. Put it on the tripod after removing it and secure it with the middle screw.

●The 50L rotary evaporator should not be left before packing.

●When filling the 50L rotovap the brake screw must be fastened or launched according to the kind of device.

●Check the soundness of the tools and the natural end result to avoid damage to the system throughout transport.

●When the fund has an abnormal distribution, we should find out the trigger before the coverage. It is strictly forbidden to press hardcovers and covers.